2021, as the first year of the 14th Five-Year Plan, is the historical node of the centenary of the founding of the Party, and it is also a year of deep integration of mainstream media. This year, good news spread frequently in the aerospace field, and the China Olympic Corps fought bravely in Tokyo. Also in this year, the mainstream media continued to attack the Internet position, making every effort to create media-integrated reporting products with a more comfortable attitude, and exerting the public opinion guidance of the mainstream media on the new media side.

Based on this, CTR evaluates the network communication power of mainstream media institutions through industry observation and data monitoring statistics in 2021, forming a list of network communication power in 2021, and objectively presenting the network communication effect of mainstream media.

Results of the list of mainstream media network communication power in 2021

According to CTR’s systematic evaluation of various central media in 2021, the biggest fans of CCTV, People’s Daily and Xinhua News Agency in new media channels are all above 100 million, and the effect of integrated communication ranks in the top three.

Legend: Evaluation results of communication power of major central media networks in 2021

According to CTR monitoring data, by the end of 2021, eight central media had nearly 100 self-owned APP products and 1,600 accounts opened by third-party channels, forming nearly 440 account matrices of the third-party platform with more than one million fans (or with a cumulative reading of more than one million in a quarter), and accumulated about 24,000 explosive short video content and 47,000 explosive WeChat official account articles. Compared with the beginning of the year, the cumulative download volume of the central media’s own APP increased by 13.8%, and the mainstream media’s entry into the main position of the Internet was further accelerated, and its communication power and influence continued to expand.

The channels of the Central Radio and Television General Station developed in a balanced way, occupying the first place in many sub-stations. There are 14 self-owned client products with downloads of more than one million, with the growth rate exceeding the industry average, among which the growth rate of downloads of "Central Video", "Cloud Listening" and "CCTV Literature and Art" doubled; Head and Shoulder Account Matrix with over 220 million fans/quarter cumulative reading. In 2021, the main station produced 18,000 explosive works, of which "CCTV News" Tik Tok and Aauto Quicker accounts accounted for more than 90% of the explosive works.

The list of network communication power of 38 radio and television organizations at or above the provincial level shows that the Central Radio and Television General Station, Hunan Radio and Television and Shanghai Radio and Television are among the top three.

Legend: In 2021, the network communication power of 38 radio and television institutions above the provincial level was TOP10.

Hunan Radio and Television has its own channels, Xiaomang and Fengmang have been launched one after another, enriching its own product matrix and striving to build its own platform.

Shanghai Radio and Television and Zhejiang Radio and Television have developed in a balanced way in third-party channels, and Weibo, WeChat, Short Video and other third-party platforms are on the list.

Henan Radio and Television has made rapid efforts in WeChat and short video channels, ranking fifth in this year’s comprehensive list and second in the short video sub-list.

Beijing Radio and Television and Jiangsu Radio and Television have performed well in Weibo, its own APP and other third-party platforms, but the strength of short video channels is slightly weak, which has a slight decline in the overall ranking.

Hubei Radio and Television and Shandong Radio and Television entered the list for the first time this year. Hubei Radio and Television has improved its ranking in all channels, with Weibo and short video channels in the TOP10. Shandong Radio and Television has made rapid efforts in its own channels and short video channels, forming a three-level media account matrix with "Lightning News" as the core and provinces, cities and counties (districts), ranking in the top ten in its own APP and short video sub-list.

Highlights of mainstream media network communication in 2021

(1) The theme main line reports hit the floor, creating a red explosion IP.

The new media will broadcast live and create related topics to aggregate the attention of the whole network. The live broadcast of "July 1st Medal Awarding Ceremony" and "Celebrating the 100th Anniversary of the Communist Party of China (CPC)" by CCTV News, the Central Radio and Television General Station, attracted nearly 80 million people to watch, and the topic of creating Weibo # 100th Anniversary of the Communist Party of China (CPC) # exceeded 12 billion. The National Day live broadcast "National Day Flag Raising Ceremony" was watched by over 10 million people. The People’s Daily set up the topic of July 1st Weibo # General Secretary’s Golden Sentence of the July 1st Medal Awarding Ceremony #, with a total reading of over 60 million, and a single golden sentence of Weibo praised over 70,000; On the National Day, the live broadcast window was opened through the Weibo platform, with 1.72 million viewers.

Creative expression enriches product forms, and frequent explosions are popular among netizens. The original domestic cartoon "Zhenshanhe" of China Central Radio and Television General Station has been played over 1.5 million in Weibo. The People’s Daily released a mixed-cut MV "The Centennial Edition of the Founding of the Party", with revolutionary historical film and television materials and the melody of popular songs on the Internet. The total broadcast volume in bilibili and Weibo was 9.56 million; In conjunction with Hunan Radio and Television and Tencent Music, the special music concert "No.100 Fuxing Avenue" was planned, and the total broadcast volume of the client video series exceeded 4 million. Zhejiang Radio and Television launched H5 works "Look at the Digital Paradigm in Zhejiang" and "Hello, Zhejiang! ",etc., to create an immersive reading experience, with a total reading volume of over 100,000.

The perspective of "sticking to the ground and innovating" ordinary characters cuts into the netizens’ empathy. In the national day special report, the mainstream media have shown their patriotic feelings from the perspective of ordinary people, which triggered empathy among netizens. Tik Tok Street’s "CCTV News" by the Central Radio and Television General Station was praised by 1.257 million people, and it was listed on the hot search list of Weibo across platforms. The People’s Daily adapted online celebrity’s song "The Sea of Stars" and invited ordinary people from all over the country to appear and sing. The video of Weibo was played more than 7 million times. Xinhua News Agency interviewed ordinary people, showing the sincere and touching patriotic feelings of the general public. Among them, the video broadcast of veterans insisting on raising and lowering the national flag exceeded 700,000.

(B) The reporting of major public events changed the way of discourse, and diversified reporting resonated with netizens.

Aerospace reporting has both feelings and interests. According to CTR monitoring data, the mainstream media released 2947 explosive works with aerospace theme this year, with a total broadcast volume of over 1.84 billion times and a total interaction volume of 440 million times. The Weibo account matrix of the Central Radio and Television General Station released a total of 286 explosive works, with a total praise of over 12 million; The cumulative broadcast volume of space-related live broadcasts released by the central video platform "Dream in the Sky" exceeded 10 million times; "CMG Watch" Weibo account created Weibo topic # Kung Pao Chicken in Space Station #, and invited many star artists to sing the limited single "Kung Pao Chicken in Space Station", with a total reading volume of 34.159 million. The People’s Daily has accumulated 1,200 explosive works, including 256 explosive works of Weibo account, which has been praised 9.12 million times; Launched the # Travel Diary of the Space Trio # to record the details of the space life of the Shenzhou-13 astronaut, with a total reading of over 13 million.

Sports event reports are full of colors, encouraging Olympic athletes to show their sportsmanship. During the Tokyo Olympic Games, the total number of viewers on the all-media platform of CCTV exceeded 47 billion, setting a new record for the number of sports events in the past 10 years. In terms of content planning, CCTV news client aggregates content resources, creates Olympic special topics, and opens 11 sub-sections such as "Event Express", "China Legion", "Watching Games", "Olympic Story" and "Come to the main station to watch the Olympics" to present relevant contents in different categories. The central video client grasps the preferences of young users and skillfully uses "national wind elements" to create a traditional cultural experience program "National Wind Games", with a cumulative broadcast volume of 16.028 million. The People’s Daily used posters to attract users’ attention, and launched the poster "Long Picture of Triumph" to record the wonderful performance of China Olympic athletes in the form of cute version of comic books. The cumulative praise of this Weibo was 112,000, and the cumulative forwarding volume was 31,000. Posters of characters from the national anthem were launched, and the heroic moments of athletes winning gold medals were embedded in the five-line map. The creative works were praised 74,000 times and forwarded 28,000 times. Xinhua News Agency released a series of videos of "Olympic Early Know" on its account, and added a situational theater to increase the interest of Olympic news reports. The cumulative broadcast volume of 14 videos was nearly 3 million.

(C) New media creative programs spread in circles, innovative advertising implanted to upgrade content marketing.

Mainstream media actively use new media thinking to realize content and form innovation and create circle codes. This year, CCTV launched the host talent show "Summer of young", which became the password for this summer, and then relied on the Beijing Winter Olympics to launch "young in Winter". The "Yang young" series focuses on "contrast", which on the one hand fully shows the host’s personal talents, on the other hand presents rehearsal mistakes and private tidbits in short videos, showing real and personalized content, and is loved by netizens. According to statistics, the five-hour live broadcast of the central video platform "Summer of Central young" earned 63.53 million viewers, and the program-related topics won 41 hot search lists on the whole network, with a total reading volume of 3 billion, a total interaction volume of 4.54 million, and a short video broadcast volume of 700 million times. "Summer of Central Young" has become a landmark program on the new media side of the main station in 2021.

Business advertisements are cleverly implanted, and customized content is adapted to the scene. The Central Radio and Television General Station fully considers the adaptability of products and scenes in advertising brand implantation and conducts customized content marketing. Including the adaptation of the theme song "Song of Leo" by Haier Brothers to arouse the memory of the brand among netizens, and the related Weibo topic # Wang Bingbing and other anchors strung together 14 domestic animations # with a total reading of 110 million. The host experienced the cooking, sports and wearing choices in the home smart scene, and the netizens were able to personally bring themselves in and empathize with the scene, which helped the short video of commercial advertisements spread widely in the new media. The cumulative broadcast volume of related Weibo topic # Wisdom was 69.725 million.

(D) Radio and television media differentiated to create their own APP matrix, and audio and e-commerce positions rose.

According to CTR monitoring data, in 2021, there were more than 150 self-owned apps updated by radio and television organizations in normal operation, and the overall cumulative download volume increased by 19.1% compared with the beginning of the year, and there were 43 apps with download increments exceeding one million. Central Radio and Television General Station, Hunan Radio and Television and Shanghai Radio and Television ranked in the top three in the 2021 self-owned APP sub-list. The Central Radio and Television General Station has its own APP video and CCTV news client upgraded and revised. The central video pays more attention to the creation of social functions, attracts a large number of high-quality social accounts, and increases the creation of "Central Friends Circle" and vertical content sections; CCTV news pays attention to the user experience, and the new "24-hour" time stream presents the global key news, which is convenient for users to use the fragmented time to browse the current hot spots; Add emergency information collection capacity, start information collection at the first time when a major accident occurs, help rescue work, and reflect the social responsibility of mainstream media.

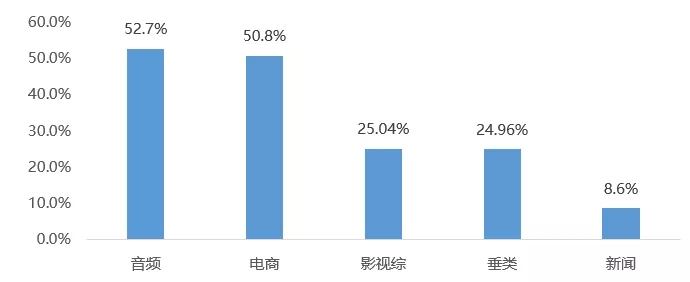

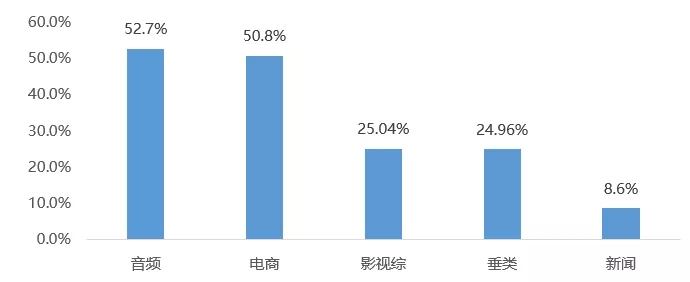

On the whole, radio and television organizations pay more attention to the creation of their own APP head products. More than half of the head products have been systematically updated in the past month, and 8 of the TOP10 apps have been systematically updated in the past 7 days. Among the main categories of radio and television APP products, the cumulative download volume of audio and e-commerce APP has increased by more than 50%.

Legend: In 2021, the growth rate of self-owned APP downloads of 38 radio and television institutions above the provincial level.

Legend: In 2021, 38 radio and television organizations at or above the provincial level spread their own audio APP product TOP5 on the Internet.

E-commerce APP is the key area of mainstream media this year. Hunan Radio and Television Xiaomang APP starts from Hanfu Circuit and builds a "trendy domestic content e-commerce", always aiming at young users and differentiating to build a vertical e-commerce platform. Shanghai Radio & TV, on the other hand, accepts the user traffic of BTV through the B+ Mall section, creates a content-consumption link, and constructs a new shopping application scenario through program content drainage.

(E) Continue to launch short videos, and the radio and television media will give full play to the advantages of content and layout features.

In 2021, radio and television organizations will spread their matrices on short video platforms (Tik Tok, Aauto Quicker and CCTV) to a large scale, and their output will be stable. By the end of 2021, there were over 470 head and shoulder accounts with over one million fans in 38 radio and television organizations at or above the provincial level, among which 48 head accounts with more than 10 million fans increased by 92% compared with the same period in 2020, and the proportion of head accounts reached 11%, maintaining rapid growth for two consecutive years. The data shows that the short video platform still maintains a strong vitality, and radio and television organizations are increasingly adapting to the rules and gameplay of the short video platform, and making efforts based on their own superior resources to create vertical content products with radio and television characteristics.

Legend: In 2021, 38 radio and television organizations at or above the provincial level ranked TOP10 in terms of short videos of network communication power.

According to CTR monitoring, in 2021, there will be 10 head and shoulder accounts with a fan growth of more than one million in CCTV. Among them, Tik Tok, a Chinese Poetry Conference, and Aauto Quicker, a young video, are the top two in terms of growth, with the former presenting large-screen classic IP in short videos, and the latter relying on sports program resources to create new IP for sports.

The "Tang Palace Night Banquet" helped Henan Radio and Television to successfully go out of the circle, and the "Luoshen Shuifu" and "Longmen King Kong" pursued by winning the battle were sought after by netizens. Henan Radio & TV Station has implanted Internet communication genes such as "interactive, open and empathetic", edited the core wonderful content, and rapidly spread and continued to ferment with short, intuitive and convenient short video communication forms, creating a long tail effect and maximizing the communication effect. Tik Tok, the "Elephant News", launched the 2021 Henan Spring Festival Evening Collection, bringing together the highlights of the program, with a cumulative broadcast volume of 240 million times, and the number of account fans increased by more than 8 times compared with the beginning of the year, making it the account with the highest growth rate of 10 million account fans in radio and television organizations.

By the end of 2021, Shandong Radio and Television had aggregated short video accounts of more than 200 provinces, cities and counties on the short video platform, with a cumulative fan base of 120 million and a cumulative interaction of over 700 million times, which was very influential in the province.

In addition, 38 radio and television organizations at or above the provincial level have made use of the traditional proprietary content IP to build the Internet, and the number of Tik Tok accounts of 17 programs has exceeded 10 million, an increase of 9 compared with the beginning of the year. According to the monitoring data of CTR short video user portrait products, the age structure of these accounts is mainly people over 30 years old, who care for their own health, pay attention to maintenance and fitness, pay attention to financial investment and are willing to pay for health. On the whole, these users belong to the backbone of society and have strong consumption potential, which brings broad prospects and opportunities for radio and television institutions to expand the large-screen realization model and dig deep into the value of Internet users.

(VI) Moderator reporter Wang Hong transmits positive energy in various forms.

With the mainstream media all marching into the main battlefield, radio and television hosts and journalists continue to adhere to the traditional media people’s duty of keeping upright, and combine their own advantages and positioning to carry out diversified communication on the new media side. According to CTR index, Tik Tok, Aauto Quicker and Billie Billie’s head host account number is 8, Zhejiang Radio and Television 3, Jiangsu Radio and Television 3 and Anhui Radio and Television 1, with CTR index all exceeding 70.

IP, the host and reporter of the Central Radio and Television Station, showed their magical powers, and displayed personalized content on platforms such as Mile Mile and Tik Tok to create personal brand characteristics. The account of "Eat Pepper’s Meow Sauce" (Wang Bingbing) published interview tidbits and personal life Vlog, which continued to maintain its high influence with a sweet and lovely image. Among them, the work "Ice Ice vlog.003" recorded the leisure daily life of Wang Bingbing visiting hutongs and slapping cats, with a total broadcast volume of 10.639 million and a total interaction volume of 1.405 million. The account of Liu Xiaoqian, a foreign correspondent, records the daily work abroad and sends back the latest news overseas, showing the fearlessness and professionalism of China reporters. The work "I am willing to be interviewed by the China media" interviews Blake’s father who was shot by the police on the street and exposes racial discrimination in American society, with a total broadcast volume of 3.026 million and a total interaction volume of 158,000. The host "Li Sisi" account, "Zhu Xun" Tik Tok account and Aauto Quicker account share daily life, convey happy mood and show the orthodox host style; "Host john young" Aauto Quicker account recorded funny sitcoms to amuse the netizens; The "Scarab" account in Tik Tok is deeply involved in children’s education and awakens the childhood memories of netizens.

Among the provincial radio and television stations, Tik Tok, the news sister of Zhejiang Radio and Television, Tik Tok, Wang Xiaochuan of Anhui Radio and Television, Aauto Quicker, Dalin Review of Jiangsu Radio and Television, Aauto Quicker, the reporter Yang Wei, and Billi account are outstanding in the field of news commentary, actively advocating correct values. Tik Tok account of "Xiaobei-City Private Car" of Zhejiang Radio and Television has been deeply involved in the field of urban traffic and private car transactions, realizing the visualization of traditional urban traffic broadcasting, and the host’s capable and provocative behavior style has been loved by netizens. Shen Tao’s Tik Tok account of Zhejiang Radio & TV Station continued its variety entertainment style, shooting various jokes with daily life as the theme, which triggered interaction among netizens. In addition, live broadcast with goods has become a new trend, and the professional performance of the host is rich in the live content ecology.

(7) Enter the virtual human track and actively embrace the frontier technology of the meta-universe.

In recent years, the virtual idol industry is in full swing, and the virtual image is the core element of the meta-universe. Getting involved in virtual idols is the fastest and most feasible way to enter the meta-universe. Once the meta-universe concept virtual beauty expert "Liu Yexi" was launched, Tik Tok’s powder rose more than 3 million in a week, which shows that the development prospect of virtual idol track is broad. Many mainstream media have tried to build virtual hosts and journalists.

The Central Radio and Television General Station launched the Winter Olympics sign language AI anchor. Based on technology, it can not only report the news of the Winter Olympics synchronously, but also provide timely, accurate and smooth sign language live broadcast for the hearing impaired. Xinhua News Agency launched a digital journalist and astronaut Xiao Qian, and created a realistic virtual Martian surface to lead netizens to feel the meta-cosmic news.

Shanghai Radio & TV Station launched the second-dimensional virtual news anchor Shen Ya to show the possibility of deep integration of virtual reality in news broadcast, and opened the Official account "Shen Ya _ Xiaoya Official", with 72,000 fans, a total broadcast volume of 3.908 million and a total praise volume of 742,000. At present, Shen Ya has participated in multiple live news broadcasts, character dialogues and news reports. Hunan Radio and Television launched Xiaoyang, a digital host, and opened an account "Xiaoyang -Young" in Weibo, mainly to promote Hunan Satellite TV programs.

(8) Make efforts to spread overseas, and the role of mainstream media in global news reports is prominent.

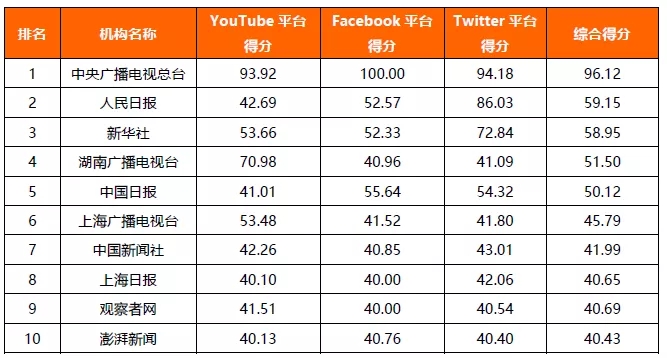

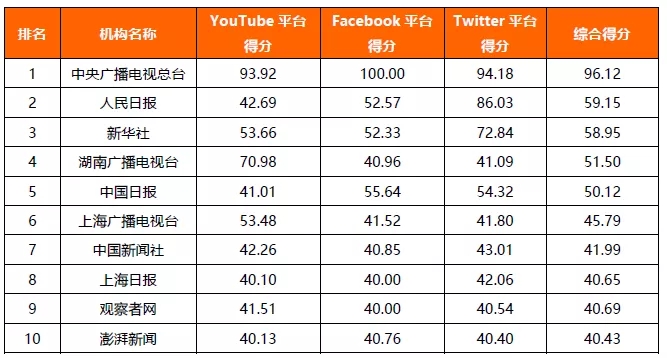

According to CTR monitoring, by the end of December, 2021, more than 30 domestic radio and television organizations or central media had opened nearly 700 accounts on three overseas social platforms, with a cumulative fan base of over 1.1 billion, of which Facebook platform had the largest fan base, which exceeded 1 billion as a whole, with the fan base increasing by 9% compared with the beginning of the year, and there were 18 head accounts above 10 million. Among them, CCTV (@ChinaGlobalTVNetwork) and China Daily (@chinadaily) both have more than 100 million fans. The total number of fans on YouTube platform is 38 million, which is growing rapidly, and the overall number of fans has increased by 24.9% compared with the beginning of the year. Among them, 10 accounts of CCTV, Xinhua News Agency, Hunan Radio and Television, Zhejiang Radio and Television and Shanghai Radio and Television Institutions have more than one million fans. The total number of followers of Twitter platform is 57 million. Due to platform restrictions and many other reasons, the number of followers of domestic institutional accounts has grown slowly, with an overall increase of 0.6% compared with the beginning of the year.

Legend: TOP10 list of overseas communication power of domestic mainstream media in 2021

In the face of the complicated international situation in 2021, the domestic mainstream media will improve the ability of public opinion to control the field in an all-round way and break the discourse hegemony of western media through exclusive and objective reports. In the report on Meng Wanzhou’s return to China, the Central Radio and Television General Station conducted exclusive live broadcasts simultaneously on its own new media platforms such as Central Video, CCTV News Client and CCTV. The total number of praises exceeded 400 million, and all 17 contents were launched on the whole network; The live broadcast signals and news materials were broadcast and reprinted by 391 media outlets in 58 countries and regions, including Associated Press, AFP, Reuters and European Broadcasting Union, with a total broadcast time of over 2,800 times. In the report that the Taliban came to power in Afghanistan, the local reporters at the general station sent back the live report for the first time, and the related video broadcast volume exceeded one million; Wei Tian, the anchor of CGTN, spoke to the Taliban government spokesman live, and his professional performance was recognized and praised by overseas netizens, with a cumulative video broadcast of 110,000 times; The "CGTN Frontline”Facebook account released photos to show the cruelty and humanistic care of the war, and the average interaction volume was above thousand.

Facing the western countries’ deliberate smearing on issues such as the source of the epidemic and Xinjiang cotton, the mainstream media launched a series of bilingual works, with detailed evidence to vigorously fight back and safeguard the national image. CGTN, the Central Radio and Television General Station, launched "In-depth Investigation of Covid-19 Laboratory in North Carolina, USA" on the YouTube platform to disclose the truth about the source of Covid-19 in Debao Laboratory in the United States; A series of video "Facts tell" was launched to ask questions about the focus issues, which triggered users’ in-depth thinking and discussion, making the truth self-evident. The YouTube account of Shanghai Radio and Television’s "ShanghaiEye Magic Eye" released the news "The polar industry in Hami, Xinjiang is booming" to show the Xinjiang industrial economy that is still operating normally under US sanctions.

The literary and entertainment content of mainstream media also has bright performance overseas. The YouTube account of CCTV Spring Festival Evening focuses on the two major literary IP’s "Spring Festival Evening" and "Autumn Evening" and focuses on the attention of overseas users. Up to now, the cumulative play volume of the account has exceeded 250 million times, and the number of account fans has increased significantly during the Spring Festival and Mid-Autumn Festival. The film and television account "China Zone Drama Music Department" recommends China’s film and television works to overseas users. At present, the number of account users has exceeded one million, and a film and television drama communication matrix covering more than 10 languages including Chinese, English, Spanish, Vietnamese and Indonesian has been formed. Hunan Radio and Television opened YouTube accounts such as "Official Channel of Mango TV of Hunan Satellite TV" and "Official Channel of Night in Wan Chai" to delay the update of variety shows, among which, the total broadcast volume of the 12-stage complete program of "My Brother" was 9.783 million. Shanghai Radio and Television YouTube account "SMG Shanghai TV official channel" released the 12-stage complete program "Our Song", and the cumulative broadcast volume of YouTube platform was 9.23 million. Zhejiang Radio and Television launched a music category, and opened a YouTube account "Zhejiang Satellite TV Music Channel" with a cumulative subscription of 1.54 million.

tag

Looking back on 2021, the scale of Internet users in China has exceeded 1 billion, and the Internet penetration rate has exceeded 70%. China has become the largest and most vibrant digital society in the world. "Home economy" has become an indispensable element of life, and online shopping by over 800 million people has spawned exploration and practice in the fields of community e-commerce, social e-commerce and content e-commerce. Many new words such as "blockchain" and "NFT" have come into public view, "6G" has been written into the 14th Five-Year Plan of the Ministry of Industry and Information Technology, "web3" has been mentioned frequently by the Internet industry, and "Metauniverse" is full of infinite possibilities.

Mainstream media keep innovating in the surging Internet rivers and lakes, constantly adapt to new forms of communication, and successively launch explosive works; While strengthening the construction of its own platform, it constantly optimizes the upgrading mechanism and system, and becomes more familiar with and adapted to the law of Internet communication. We expect the mainstream media to dance like an elephant to promote the in-depth development of media integration and move towards a new future.